Insight

Smart Drydocking: Optimizing Vessel Maintenance Through Asset Intelligence

Drydocking is one of the most costly maintenance events in a commercial vessel’s life cycle. The 2025 market for cruise ship drydock and refurbishment alone is valued at over $4 billion annually, according to a report by Cruise Industry News.

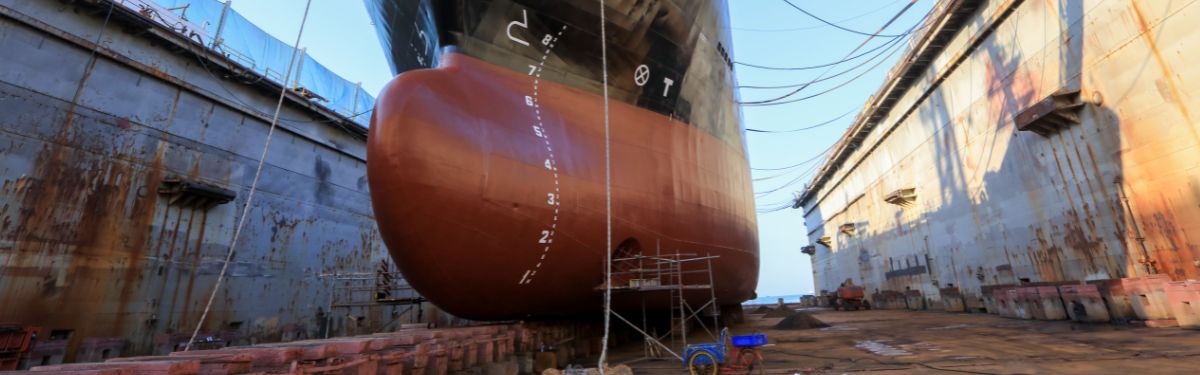

Typically required every 2-5 years, drydocking is essential to maintain the vessel’s safety, compliance and operational longevity. However, when a high-value marine asset such as a tanker goes into a drydock for routine inspections, critical repairs or system upgrades, costs can quickly add up. Strategic and efficient planning is crucial to minimize cost and complexity when an asset sits idle, generating zero revenue.

Full Suite of Integrated Services

By leveraging advanced enterprise asset management (EAM) and reliability strategies, shipowners and operators can transform this high-stakes process into an opportunity for operational excellence—minimizing downtime, controlling costs and enhancing long-term vessel performance.

The Real Cost of Drydocking

In an industry where every hour of downtime translates to significant revenue loss, drydocking presents unique logistical and financial challenges.

Costs from repairs, regulatory and statutory inspections and taking a vessel out of service can quickly escalate, often reaching millions of dollars. Unplanned issues, such as unexpected change orders or regulatory non-compliance, can result in increased costs, extended docking time, supply chain delays and further disruption to operational schedules.

To manage these risks, asset owners and operators should start planning long before the vessel enters the dock.

When operators don't have a clear picture of their equipment's condition, however, they may be setting themselves up for costly surprises such as extended downtime, budget overruns and delayed returns to service.

A proactive, data-driven approach to asset management makes the difference. With real-time visibility into equipment health and maintenance history, operators can plan more accurately, execute faster and get vessels back to work on schedule.

The Role of Enterprise Asset Management in Drydocking

Well-implemented EAM systems serve as the backbone of effective drydocking strategies, providing operators with the tools to plan, track and optimize maintenance activities. By integrating real-time data, predictive analytics and compliance frameworks, EAM empowers operators to address challenges proactively. Key benefits include:

- Comprehensive Maintenance Planning: EAM systems monitor the condition and performance of critical onboard systems such as marine propulsion systems and auxiliary equipment. By identifying maintenance and retrofitting needs well in advance, shipowners and operators can allocate resources efficiently, schedule repairs strategically and avoid surprises during drydocking.

- Life-cycle Cost Optimization: Understanding the remaining useful life of key components allows owners/operators to make informed decisions about repairs, upgrades or replacements. This approach maximizes asset value while minimizing long-term costs, helping investments to align with operational goals.

- Regulatory Compliance: Compliance with Class and other Regulatory requirements, such as those set by the International Maritime Organization (IMO) or classification societies like ABS, is non-negotiable. Well-configured EAM systems can provide visibility into such compliance deadlines and documentation, so that vessels arrive at drydock with a fully prepared drydock specification and plan to address all these requirements to avoid delays and penalties.

Enhancing Vessel Performance with Reliability-Centered Maintenance and Actionable Intelligence

While EAM provides the framework, reliability engineering amplifies its impact by focusing on preventing failures before they occur. Reliability-centered strategies shift maintenance from reactive to proactive, targeting the most critical assets to optimize drydocking outcomes. Core elements include:

- Reliability-Centered Maintenance (RCM): RCM prioritizes maintenance based on asset criticality, keeping efforts focused on systems most vital to vessel performance. By leveraging condition-based maintenance over routine overhauls, operators reduce unnecessary work, minimize downtime and lower costs.

- Failure Data Analysis: Analyzing historical data from reliability programs to identify patterns in component failures helps teams prioritize and address high-risk areas before drydocking. This predictive maintenance (PdM) approach reduces the likelihood of unexpected issues and enhances planning accuracy.

- Strategic Decision-Making: Combining EAM data with reliability insights also supports asset owners/operators in prioritizing investments and allocating resources effectively with cist reduction in mind. This data-driven approach improves decision-making processes about maintenance, upgrades and long-term operational strategies across the fleet.

Beyond the Drydock: Long-Term Gains

A strategic approach to asset management and reliability delivers benefits that extend well past a single drydocking event. Proactive maintenance becomes the foundation of an extended drydocking program, keeping vessels in service longer and improving overall fleet availability.

This approach also improves resource predictability. Minimizing unplanned repairs reduces disruptions to supply chains and logistical operations, leading to smoother workflows.

The financial case is just as strong. Optimized maintenance scheduling and life-cycle management reduce both downtime and maintenance costs. ABS Consulting data indicates that PdM strategies can achieve an average of 20-30% reductions in maintenance costs compared to traditional fixed-time approaches, allowing operators to reinvest those savings into fleet improvements or competitive advantages.

Navigating Regulatory Complexity

Successful drydocking depends on maintaining compliance with maritime regulations and safety standards, such as those outlined by IMO and classification societies. EAM systems foster traceability and documentation to facilitate compliance with standards like the International Safety Management (ISM) Code.

Additionally, advanced EAM platforms integrate with Internet of Things (IoT) sensors and predictive analytics to provide real-time insights into equipment health. These smart monitoring tools help reliability teams confirm that regulatory requirements are met while optimizing maintenance schedules.

Strategic Implementation: Lessons from ABS Consulting

With more than 50 years of experience in safety, reliability and compliance management, ABS Consulting has partnered with the global maritime industry to transform asset reliability programs into actionable intelligence. Our consultants go beyond EAM or CMMS software implementation, offering data-driven management services that extend from system selection to full implementation, integration and ongoing support. Our maritime experience coupled with our proven methodology addresses the critical elements of successful EAM implementation, delivering measurable improvements in reliability, efficiency and cost performance.

Our approach is rooted in a systematic methodology — Define, Measure, Analyze, Improve, Control (DMAIC) — to deliver measurable improvements in performance and cost efficiency. Key findings from our work include:

- Holistic Integration: Successful implementations combine technical expertise with deep industry knowledge, aligning EAM systems with operational and regulatory goals.

- Data-Driven Results: Metrics like maintenance cost as a percentage of Replacement Asset Value (RAV) and uptime for critical assets provide clear benchmarks for success. ABS Consulting’s reliability programs have consistently delivered cost reductions through optimized maintenance practices.

- Tailored Solutions: Every fleet has unique needs. ABS Consulting works closely with operators to develop customized plans with clear tasks, milestones and deliverables, resulting in seamless integration of EAM and reliability strategies.

Positioning for Success in Maritime Operations

In the expensive process of drydocking, the stakes are high: miss something and the result could potentially give way to safety issues, compliance headaches, or worse—operational failures that could have been prevented. But with a strategic approach, and by investing in robust EAM and reliability programs, the marine and offshore industries can help keep vessels safe, compliant and profitable for years to come.

For operators ready to transform drydocking from a costly necessity into an opportunity for optimization, ABS Consulting provides the EAM expertise, tools and strategies needed to succeed. Let’s work together to enhance reliability, streamline operations and secure your fleet for long-term success.

About the Authors

Jason Smith - Director, Business Development

Jason Smith is Director of Business Development at ABS Consulting, bringing over 25 years of experience in sales and operations, specializing in EAM, CMMS and reliability consulting services. He has helped numerous global organizations optimize their asset management strategies and achieve operational excellence.

Rogerio Vieira - Global Director, Business Development, Marine and Offshore

Rogerio Vieira is the Global Director of Business Development, Marine and Offshore, at ABS Consulting, overseeing strategic growth initiatives within the offshore and maritime sectors. With more than two decades of global experience, Rogerio has held diverse roles blending business, technology and operations expertise.